For the non-pilots, the rudder pedals control the rudder on the tail of the plane – the yaw. The toe portion of these pedals are the brakes. Pushing the entire pedal fore and aft with your whole foot causes the aircraft rudder to move side to side. Pointing your toes causes the top portion of the pedal to pivot and move forward which engages the brake on the main gear on that side of the aircraft. Obviously, or maybe not, applying this brake while in flight doesn’t do anything except stop the wheel from turning. Only when the tire is contacting the ground does it make any real difference.

The brake portion of the rudder pedals on my Vans RV-3 have always been too vertical for me. A relaxed seating position causes my toes to touch the brake before the rudder portion of the pedal. I’ve had to be very careful on takeoff and landing to stay off the brakes by keeping my toes very low on the pedal. This was hard to remember (for my pea sized brain) and resulted in having to move your foot on the pedal to engage the brake – not always ideal when landing a tail-dragger. Today was the day to correct this.

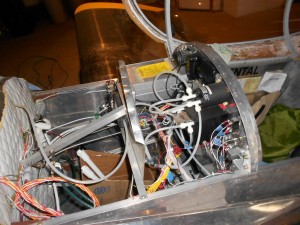

The fuselage top skin between the firewall and instrument panel is removable on airplane. This makes access to the back side of the instrument panel, firewall, and rudder pedals very easy – once you get the fifty or so screws removed. This is precisely why power tools were invented 😉

With the top skin off, I was able to get a really good look at what I was dealing with. The bracket on the toe portion of the pedal had lots of meat on it. The solution was going to be easy!! How often does that happen? My plan was to drill another hole “higher” in the extrusion to which the brake master cylinder connects. This would cause the top of the pedal to sit further forward and allow the balls of my feet to contact the pedal instead of my toes.

I removed both pedals, gave it some thought (so I didn’t create a new hole where I didn’t want it), and drilled.

Of course, nothing is easy…

The new hole in the second pedal needed to go right in a spot where a drilling was going to be tricky (on the edge of a second extrusion – causing the drill to work sideways). I decide to take it to my shop and use the drill press instead of the hand drill. A quick run home, drill the hole, and back to the hangar. I start to put things together and realize that I am missing a bolt. Ugh… A quick run home to retrieve the bolt. Back to putting things together and now I am missing a spacer. Double Ugh… A quick run home to get my collection of spacers. Finally, the re-assembly is complete and what do I spy lying on the floor of the fuselage?? Ya, the missing spacer. Ha!

The moment of truth: I take a seat in the cockpit and the brakes fall PERFECTLY on my feet! Sweet!! One just can’t ask for any better than that. Now a flight to test the change is in order. Since it was well after dinner and dark outside, that will have to wait.

While the plane was apart, I took the opportunity to install a USB socket so I can charge my USB devices while flying. I didn’t have the necessary hole saw available so I left it loose but it is connected to power and available the next time I need it.

Leave a Reply