Back to the overhaul of the Lycoming O-360 that is going on my RV-4.

All of the ugly black shellac type stuff that had built up on the engine case had to come off. Some photos of that in this post.

A few days in the solvent tank almost took care of that. It appears that I didn’t take many photos at that stage but here are a couple. You can see that there is a bit more cleaning work to be done.

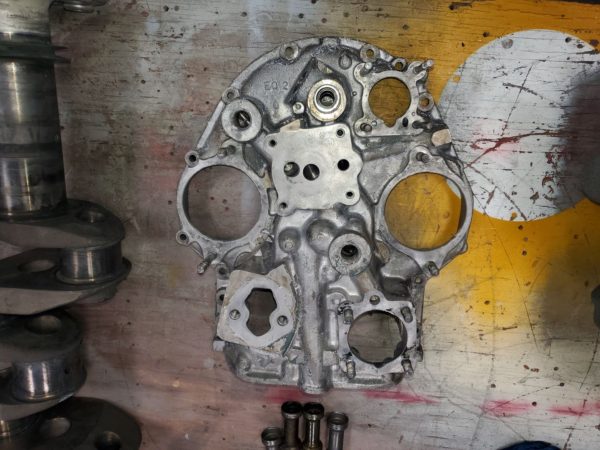

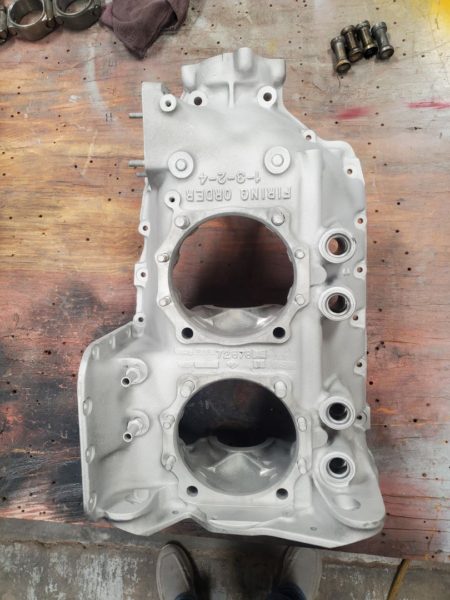

After some time in the blasting cabinet, we had this with which to work.

Before:

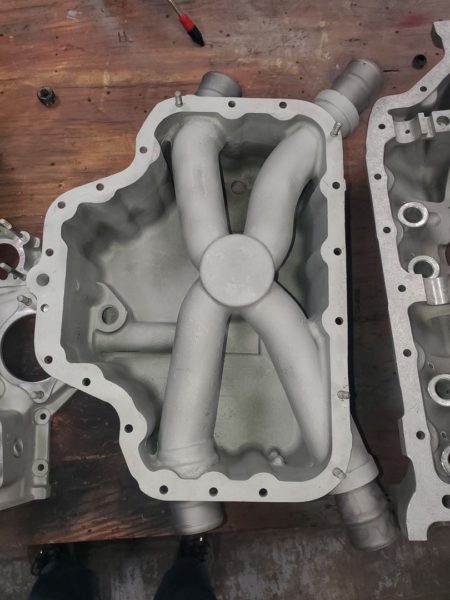

After:

The ‘sludge tubes’ can be seen in the following photo – right side just beyond the case halves. More on that below.

All the various bits look good (acceptable to use) after measureming and a thorough inspection. That is SUPER good news!

This is an engine manufactured prior to 1968 which means that the crankshaft has ‘sludge tubes’ installed (or crankshaft oil pins). We pressed the old ones out and new ones back in. Lycoming doesn’t offer much guidance on this and we had our questions. I called Lycoming and they were very helpful and answered my question – way to go Andy at Lycoming customer support!

The hydraulic lifters were disassembled, cleaned, and tested. Two of them weren’t so great and were replaced with new.

While it looks done and ready to assemble… there are a bunch of small tasks to follow.

I’m also waiting on new cylinders. Since we are living in low supply/high demand times, the wait isn’t entirely unexpected. It is a bummer though. Hopefully the wait won’t be too long. It does give me the chance to continue with a number of things that I’ve been wanting to address!

Nice cleanup Job, well done. Which cylinder have you opted for?????

Thanks Michel! I’m going with Superior Millenium cylinders. Maybe… if they are ever available again. 🙁

Jon… I’m totally in the dark relevant to what all you’re going through cleaing your engine parts. Even so the parts look brand new once you’ve cleaned them. Your project reminds me of the old fashioned way I cleaned engine parts. I know you’re doing a perfection job. Love Dad

It looks like you will end up with a new engine! So……….is the crankshaft okay so you don’t have to turn it?

Indeed!! The engine was in very good condition to start with – it had just been sitting on the shelf for a very long time (47 years). So, tolerances were all good and the only corrosion was in the cylinders (being replaced). The tear down was mostly to confirm that (no corrosion), clean all the gook (including in all the nooks & crannies, inside lifters, inside oil galleries, etc.), & replace gaskets/seals. Of course, while it’s apart, might as well replace bearings too.

Wow, you really clean parts. I hope it lasts way beyond TBO. Thanks for the updates.