Decisions made – Lycoming O-360

Given my last post (here), the question becomes; why change engines if both of my options require an overhaul? Why not just stick with what I had and minimize the effort?

Good question!

There are a bunch of reasons behind my decision.

Firstly, the O-360 with 180 hp is just a better engine. The front crankshaft bearing is better/stronger, the whole engine is stouter, it has more opportunity for ‘growth’ (as in, get more power out of it), and it includes the option of running a constant speed prop (one that is adjustable in flight). This requires pressurized oil from the engine and my O-320 does not have that option.

Little things…

My existing cowling is a very old version. It was constructed with polyester resin and was quite heavy. It was also a non-standard size at the nose so did not fit the typical 13″ spinner. I had a big gap there. It was also pretty worn and tattered.

The flange on my firewall was wearing out. Some of the ears on hinges that form the cowl attachment were starting to fail and break. This needed attention and was already pretty high on my list.

Whoever installed the carb air inlet on my cowl didn’t get it straight – and that bugged me. It was difficult to see but I could see it.

I was not happy with a number of things on the firewall and engine installation. There were spacers under the motor mount, the firewall pass thru’s were cheaply done, the air box and carb heat were not up to snuff, and on and on. None of these items were significant but given the chance, I’d sure like to fix them.

All of this together made for a swell opportunity to fix and improve a whole bunch of things. The negative is that it all takes time.

So, no time to waste. While waiting for parts, I got to work on the changes.

First was removing the old O-320 engine.

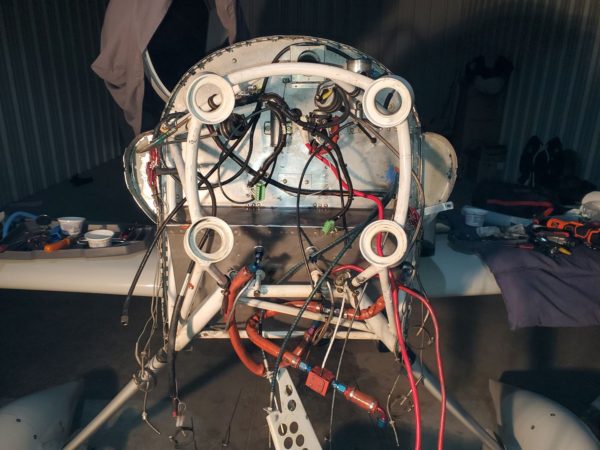

Next was getting nearly everything off the firewall.

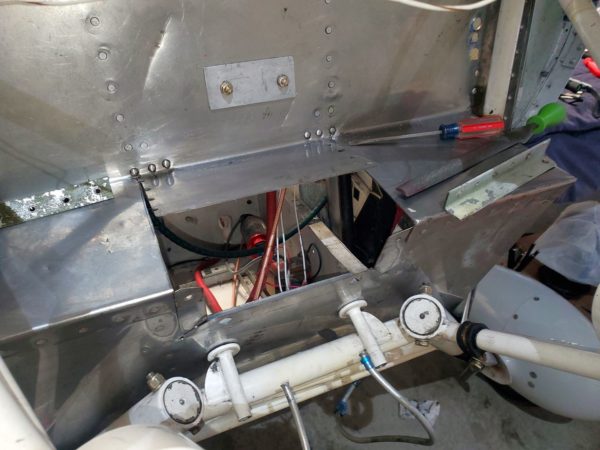

The brake lines pass thru the firewall in exactly the wrong location so they must be moved. Bleed all the fluid and remove parts.

The ‘step’ in the firewall must be modified to make room for the constant speed propellor governor that is mounted on the back of the engine. Btw; that step is the footbox for the pilot. When pressing a rudder pedal to full extension, it moves into that area.

After some careful measuring and ensuring that nothing on the other side of the firewall would be affected, it was time to commit!

Portions of the existing stainless steel firewall will be bent and another sheet of stainless steel fit to form a box. All of that will be riveted together. I’m waiting on that additional piece of stainless so progress has halted on this.

Removing the spacers under the motor mount was next. That sounds like a really easy task. Remove the bolts, pull out the spacers, reinstall the bolts. Yep… if only everything were so simple. The design of the airframe and motor mount includes the necessary ‘angles’ and I wanted to get back to the ‘right’ starting point with this new engine and cowling. Why are the spacers there? Typically they are added to account for an engine sagging and not fitting the cowling correctly.

This was a time consuming task. The landing gear is part of the motor mount so just removing the bolts would cause the rest of the airplane to drop onto the floor. That won’t work. Since nothing is easy, removing one bolt allows the mount to move slightly which makes putting the bolt back into place a real pain.

It’s hard to believe but removing those spacers from under four bolts took 7 hours. One hoist, one floor jack, one bottle jack, 16 blocks of wood, two lifting straps, and a lot of sweat. This is one of those cases where five arms would really come in handy.

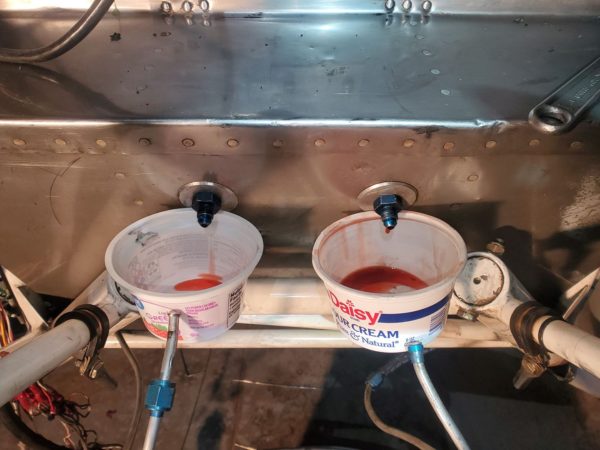

In between all of the above, a lot of parts were cleaned and polished! This is the brake fluid reservoir and engine air/oil separator.

It feels a bit slow sometimes but there is forward progress! More to come!

Looks great. I am amazed by your energy and determination.

Very nice!!

Wow! This is really interesting! No, I’m not being facetious! Thanks for all the pictures and writing!

Thanks Pete! More fun coming soon!