The time for the annual condition inspection for my trusty RV-4 had arrived. This is a very thorough inspection of every square inch of the airplane with some typical maintenance mixed in. I have a 160 hp Lycoming O-320 engine.

Progressing thru my checklist, I arrived at the borescope inspection of the engine cylinders. That was going along just swimmingly until I got to cylinder #3 and what did I spy with my little eye??

Yup, that is a crack. Cracks are bad.

My engine has approximately 3,100 hours on the bottom end (the case, crankshaft, camshaft, bearings, etc.) and about 1,500 hours on the cylinders. 3,100 hours is a lot – it definitely qualifies for social security.

So, I started researching my options. It really didn’t make much sense to replace a single cylinder on such a high time engine. Doing a complete top end (all four cylinders) made even less sense. It was time for a complete overhaul.

I started to remove the engine…

…and then boom!

A factory remanufactured Lycoming O-360 (180 hp) became available. In my opinion, this is a much better engine and includes the ability to add a constant speed prop (at some point). As a mountain pilot, there is no such thing as too much power so what could I do? Yep – I took that path.

I picked up the O-360 and brought it home. The big caveat with this motor is that it had been sitting a very long time. Like 47 years.

I know – that’s crazy! But true. The factory overhauled it in 1976.

What could the insides look like? Lycoming engines are known to have corrosion issues with the camshaft when sitting for long periods.

I drained the preservative oil and starting looking inside with my borescope. I found markings inside the cylinder that I didn’t really like.

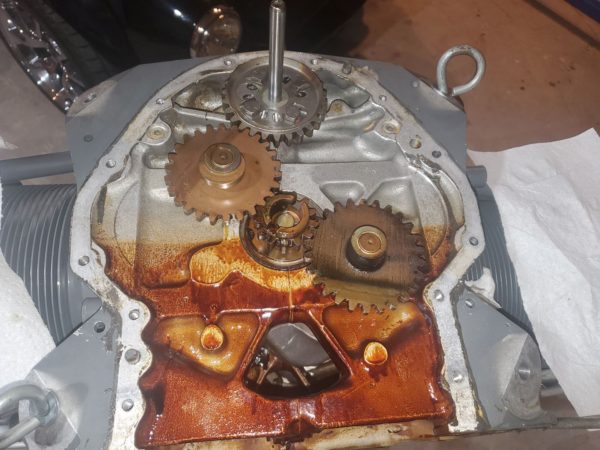

I decided to remove the accessory case and sump for a better look. The goop inside this engine was nasty. The sump had a bunch of thick gooey tar like stuff in the bottom. Everything else was coated in a hard black shellac-like coating. All this from half a century old preservative oil.

I wanted to see the camshaft.

Most will tell you that cannot see an O-360 camshaft without pulling a cylinder but I can tell you with certainty that is is possible. However; you must remove teh sump and/or accessory case. I used a borescope and could see the ‘aft’ three lobes. I didn’t like what I saw.

With that information in hand, removing a cylinder made sense.

What a surprise! The cylinder wall doesn’t look very good and the piston rings are completely filled with goop.

At this point, there was no doubt; all cylinders were coming off so a thorough inspection could be performed.

All four cylinders were the same. They just had too much corrosion to be used. A new set was ordered.

Given all that had been found, I decided to perform a complete overhaul.

Disassembly of the case was next. This time, I was pleasantly surprised – everything looked pretty good – but needed cleaned. The tappets were brand new, the crankshaft looked/measured great, and even the camshaft was good after a bit of cleaning.

New bearings and seals were ordered.

At this point, we’re waiting for parts – as far as the engine is concerned.

The airframe? It’s time for a bunch of changes!! That’s coming soon!

I am sure you were talking english…..

But maybe to just engine people!!!

Finley,

I hope you have some luck in finding cylinders for your 360. They have become REALLY hard to find. I have two months to my annual. Hope it goes better than yours. I have a friend with an RV-4 with a 360 with a constant speed and wow, does it perform. You’ll like it.

Bounds