Many asked, many wondered silently… How long could I stand to be away from flying?

It turns out the answer is two-and-a-half years. Ok… two years, seven months, and eight days – OR – 952 days – OR – 22,848 hours.

Yes, I am back in the plane game. I now own a Van’s RV-4.

I’m not sure if this is the end of the end, which was the end of flying, so now the end of flying has ended? Or, the continuation of the period before the end… of flying? I’m not even sure if a period of time that has ended can be continued…

Regardless… Isn’t she purdy!?!?!

Previously, I had a Van’s RV-3B (Daisy). The difference between the two is generally one vs. two seats. However; The RV-4 does not have a lot of rear seat weight carrying capacity once my big lard butt is planted in the front seat. So, let’s call it a one and a half seat airplane – at least when I’m flying. For now…

This RV-4 has been around awhile and has a good bit of experience but she is fine shape. The previous owner took REALLY good care of her. A few updates will be coming in the near future but, overall, she “needs” nothing.

The “S W” on the side stands for either “Second Wife” or “Something Wonderful” or… something… Or, maybe those initials will change at some point – they are just ‘decoration’ so who knows…

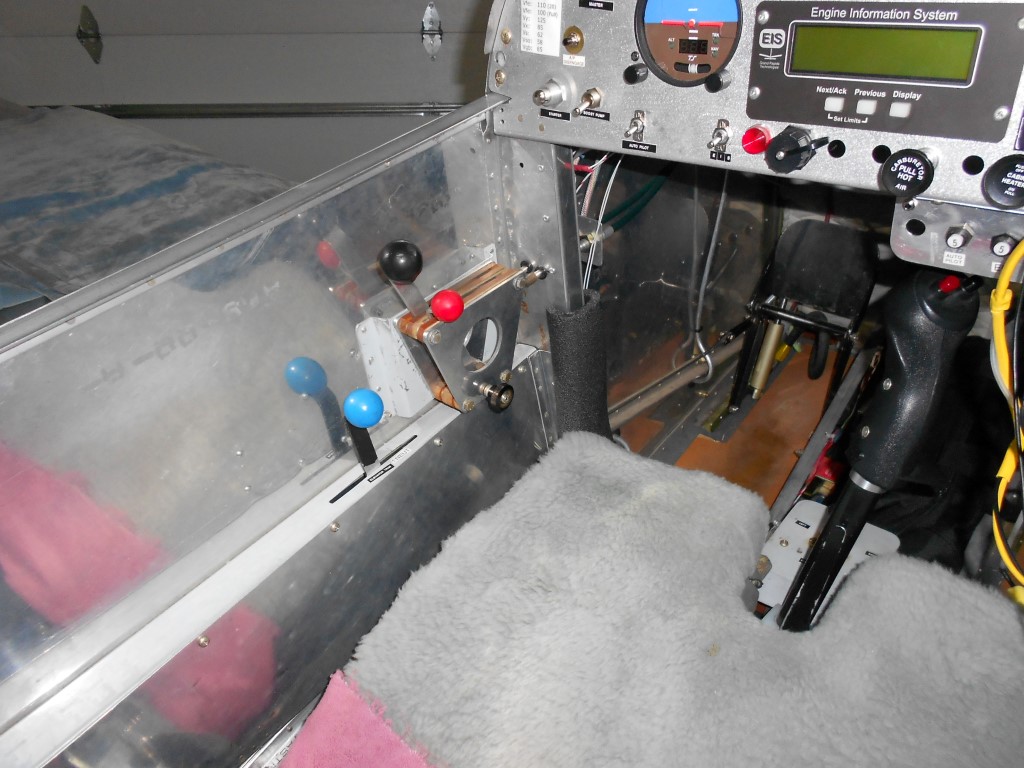

I preach aircraft familiarization to people all the time (see this post from 2012), so I took my own advice. We started off with hours and hours of ‘getting to know you’ time. This involved taking off every inspection plate, touching every wire, poking my nose into every crevice, making sure all the things that were supposed to be tight were tight and all the things that were supposed to be loose were loose. This is basically what pilots know as a condition inspection (annual inspection in the certified aircraft world) – nothing is overlooked (or isn’t supposed to be). Spark plugs cleaned and gapped, oil and filter changed, compression tested, magneto timing set, every filter and screen inspected, all moving parts lubricated, and so on…

I then spent several hours sitting in the cockpit getting the feel of things. The flight controls, where the instruments are, finding/touching/moving/adjusting controls without having to look around for them. When things get ugly – and they do occasionally, I don’t want to be looking for my reading glasses so I can see the labels on the controls to find the one I need so I can make an adjustment. Bad things happen much faster than that and a pilot’s reaction needs to be automatic, immediate, and correct – in my opinion.

We then moved outside and started the fun stuff. Engine runs and taxiing around. No, I’m not one to just jump in a new airplane and go flying. We spent a good bit of time sitting in one spot with and without the engine running making sure all was well and to get more cockpit familiarization time. Then we taxied around on the taxiway’s for a while – finding out how she feels on the ground, ensuring that the radio works, getting a good feel for the brakes, learning how cross-wind affects her behavior, and getting used to her sound.

Eventually we worked our way onto the runway for some higher speed taxi testing. Again, just figuring out how she feels and reacts on the ground at reasonable speeds.

Finally, nothing more could be done – it was time to GO FLYING!

WOO HOO!!

Then the wind started blowing. …sigh…

It blew for a week. Well… four days, but it felt like a week.

That gave us LOTS more time to sit in the cockpit and do more familiarization.

Finally the wind stopped and we went flying!

WOO HOO!!

For those with RV-4’s and might be interested, the three significant items that I found were:

- The bolt connecting the two elevator bell cranks to the pushrod bearing was a bit loose allowing the elevators to move independently (about 1/4″ at the trailing edges).

- The control stick assembly is held in place by two rod-end bearings mounted to the structure using two nuts (on the rod-end). The nuts on the front bearing were loose causing side to side motion and slop in aileron control.

- The bracket holding the front of the flap motor was not trimmed properly and was binding (which was detected as unusual noise during operation). This was preventing the flap motor/jackscrew from following the slight arc that was required and causing some binding in its motion.

The first two were very simple fixes, just tighten things up. The third one was a real pain! Getting the flap motor/jackscrew out required FAR more effort than a few bolts would imply.

As I said, she has no “needs”. However; in the “want” list… I would add a full swiveling tailwheel, EIS (engine information system), and glass panel (EFIS – Electronic Flight Information System) on the list!

I’ve already written my letter to Santa Claus so fingers crossed that he delivers! If any of you would like a copy of that list, maybe to surprise me(!!!), just let me know.

I should mention, I’ve already ordered the full swiveling tailwheel parts so don’t buy those for me… if you were thinking of doing so…. 🙂

Are you putting down ‘roots’ (of sorts)? Where is this plane?

You just like to knock of off of our feet once in awhile, don’t ya?!!

LOL!

I bet you jump right to the last page when you read a book, don’t you?!?!?

Come to think of it, isn’t this one of the characteristics of a good book?? Just when you get comfortable with things – WHAM!! – a big change in direction! 🙂

It sounds like you have another project, albeit, not as large as the last one!