The weather guessers were telling us that the weekend would be a bad one for flying.

Both days?!?!?

I know… crazy!

That is nearly unheard of here in paradise – two bad flying days in a row.

When I initially moved from the frozen tundra of the north to paradise, I nearly wore myself out. My old life demanded that on the rare occasion that a good day presented itself, I had to rush out to the airport and do a bit of flying. So, about three times a year I found myself rushing to the airport.

The first day in paradise I looked outside and it was beautiful! I jumped in my plane and flew.

The second day I looked outside and it was beautiful! I went flying.

The third day I looked outside and it was beautiful! I went flying.

After about two months of this I was exhausted! I had to stop and analyze this quandary in which I found myself. Clearly things had changed and a new plan was required. Flying just because it was a beautiful day was no longer workable.

So, for those not familiar, two sequential days of poor flying weather represents a very odd weather pattern!

It also represents a window for some maintenance!

I’ve had a bunch of stuff waiting for such a window. So, I sprang into action.

It might be worth first mentioning that installing an entirely new instrument panel and EFIS, as mentioned here, is still a goal. However; it is has been sidelined for now. Mostly due to cost and higher priority items stealing from that fund.

Most airplanes have a thing called a ‘transponder.’ Basically, it communicates a code to the air traffic control (ATC) guys. This code may be one that you and ATC have agreed on or one of the generic pre-established codes. It is an easy way for them to see you on radar and possibly even know who you are and your intentions. Sorta… it is more complicated than that. For me, it is barely used. I avoid busy airspace as it means there are people nearby. I’m required to have it when near certain airports or above 10,000′, so I have it.

The transponder that I have is very old. That means the knobs and lights barely work but worse, it looks like a part from a Model T. Can’t have that in high-tech time travel machine now can we!!

Being a cheapskate, I recently found a fellow selling a not terribly old transponder that matched the styling of my aviation radio (transceiver). So, I bought it. Now was an opportunity to get that installed.

Additionally, I have this REALLY cool fighter airplane looking control stick with all sort of buttons and switches on it. Connecting all of those to stuff is kinda not easy. I found a really neat “Ultimate Trim Relay Board” from PHAviation that makes this much less difficult. I wanted to get that installed so I could take advantage of more of these buttons and switches.

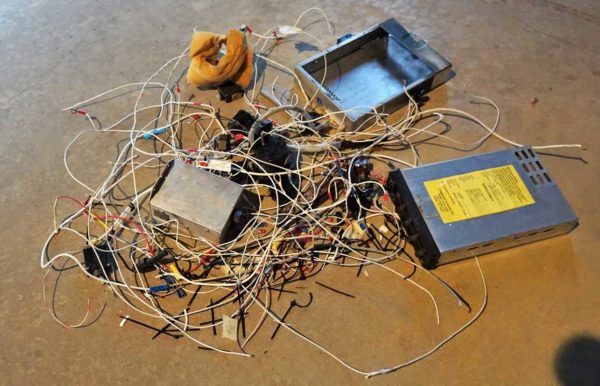

Since my airplane is thirty years old, she has lots of old and less than ideal wiring. No different than me I suppose… In any case, hers is easier to rehabilitate. I’ve intentionally NOT shown photos of this, it is a bit embarrassing. You’ll just have to use your imagination. However; I will show you the pile of stuff left laying on the ground after this project was complete!

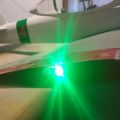

Aircraft landing lights work about like automobile head lights. However; it is not uncommon to have an option switch setting that causes them to flash in an alternating patter. We call this wig-wag because the lights on each of the wings tips flashes back and forth. This is purely for visibility. It is amazing how much easier and aircraft is to see from the air when the lights are flashing like this. When I installed LED landing lights, my wig-wag controller stopped working. LED lights require a more sophisticated controller. I had purchased this controller and was looking for an opportunity to install it.

I also use a number of electronic devices in the cockpit these days. Having some USB ports for charging these devices would be really nice. Some devices aren’t used in the cockpit but being able to charge them while enroute is helpful.

Finally, the outside air temperature (OAT) is important to a pilot for a number of reasons. The EIS had previously installed included the ability to report this information but I had not installed the sensor. It was time to get that done.

So, those were the big items on the list and I dove right in. The airplane was opened up, a bunch of old wiring was ripped out, new parts were installed, and new wiring was added.

The almost end result looks like this. I wish it could relay the number of hours of staring, thinking, and walking back and forth testing one wire at a time to ensure everything is connected to what I think it is connected to.

The only real negative to this type of work is that I am old. In my case, old age and laying on your head for hours or walking back and forth, back and forth, and climbing in and out and around… Well… it just makes an old guy ache. And ache I did!! Lucky for me, there are some neat little pills at the local pharmacy that help with that!

The initial smoke test is always scary – especially when dealing with expensive aircraft radios/components. I am happy to report that all the smoke remained inside all components!

The next test was to roll the RV-4 outside and fire her up.

That test was also a success. She started, the alternator was charging the battery, all components were working, the sun was shining and the birds were singing.

That left me with no option but to go flying. That too was a total success!

The pilots reading this are probably wondering about the upcoming requirement for ADSB compliance. I’m lucky to be one of those folks to which it doesn’t apply – except for my occasional foray above 10,000′. So, I am waiting and watching. It seems to me that the options are increasing and the cost is decreasing. I’m betting that after the January 1, 2020 deadline, the prices will be more attractive. So, I am in no rush. Of course, I hope to have that EFIS installed by that time and that will make the “in” portion of ADSB very easy.

Very nice the top comes off your panel, I have spent hours laying upside down under a panel. So I can feel your pain. You mention tundra, are you from Alaska?

Many times equipment I was working on failed that smoke test and even when the gov in paying, it feels bad. I have more than once had my own equipment fail that test and it made me sick.

Thanks for posting the improvements being made on your time machine.

Thanks Thom! No doubt that Van did a great thing making that top section removable. Other planes that I’ve owned required the gymanstics that you mention to work behind that panel. That was miserable when I was young – not sure it’s even possible anymore! 🙂

Well… not exactly Alaska. I’m from Montana and spent eleven years in Minnesota before finding paradise.

Happy New Year fellow pilot.

Thank you Thom! Happy New Year to you as well!!