Aircraft engines of the type that I fly typically have dual magneto ignition. Each magneto powers itself (does not require battery/alternator power) and fires its own set of spark plugs. So, you have two spark plugs per cylinder. This is good for redundancy but also necessary to get all the fuel burnt as the magnetos don’t provide a super-hot spark nor are the flow patterns in the cylinder very good – compared to modern engines.

Of all the parts on a Lycoming/Continental engine, I would bet that the magnetos are the things that fail most frequently – just an observation.

Recently, three of my flying friends had magneto problems – practically at the same time. I knew this was a very bad thing for me. It seems magnetos have a “sympathy failure” behavior. So, the other day when I went out to fly, I was not shocked when one magneto was not operating correctly when I did my run-up. It did eventually start working but I knew what was happening – slow failure. I immediately ordered a replacement.

Magnetos have fixed timing and a weak spark so their efficiency in terms of burning fuel is a bit lacking. Electronic ignitions are available for aircraft engines but they are usually a bit complicated as many of them require electrical system changes to ensure a backup power source. Many require additional equipment to be mounted to the engine (sensors and such).

P-Mag to the rescue!

However; there is a product call a P-Mag that is a drop in replacement for a magneto. It is self-powered like a magneto, provides a high-energy spark, offers an advanced timing curve based on manifold pressure, and allows you to run automotive spark plugs. The spark plug thing doesn’t sound like a lot but a $2.00 spark plug compared to a $50.00 spark plug is a big deal – especially when you have eight of them!

What replacement did I order? A P-Mag, of course. Brad at E-Mag Air is fantastic to work with – AA++ customer service. I explained what I had and he shipped me everything needed to install the P-Mag.

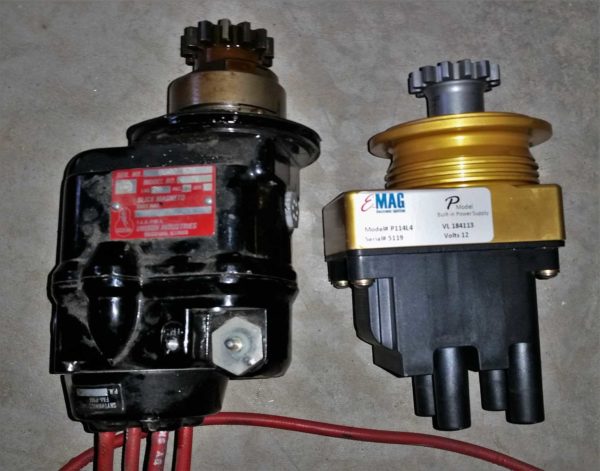

Here is the new P-Mag along with the older Slick magneto.

The installation was easy but did require a few changes.

First, I had to install a vacuum line from one of the cylinders to pick-up manifold pressure. The port used typically a primer port. The only trick to this, I am told, is to include a restrictor in the line to smooth out the pulses. I accomplished this by driving a solid aluminum rivet into the AN-4 fitting and then drilling a tiny hole in the rivet.

A twelve volt power supply is needed to power the P-Mag for starting. It then powers itself once running at a certain RPM. This required an additional circuit breaker in the electrical panel.

The left magneto that was removed had a spacer and long studs into the engine case. These had to be removed and short studs installed. Removing and installing the studs requires working with nuts right next to the gaping hole in the engine case (where the magneto used to go). As you can imagine, dropping a nut into the engine would not make for a wonderful day so caution is required. I find it interesting that I can work with nuts and bolts all day and never drop one. But! When working like this – with that big gaping hole staring at you – it is nearly impossible to hang onto those little nuts!! Stuffing a rag in the hole is the way to go for a klutz like me!

The P-Mag is hard to see but it is the gold and black component tucked under the motor mount.

Total time to remove the old magneto and install the P-Mag was about ten hours. Working at my typical, slow pace, of course.

The first flight – and all subsequent flights – with the P-Mag was a total success . I was quite surprised at how smoothly the engine ran. While I wish there was a massive increase in power, there is not (nor is that supposed to be one of the advantages). However; there should be a reduction in fuel flow which will be very nice.

I would have had a rag in that hole too! It seems like a pretty good job for being simple. It is hard to see so you must have had to move all that stuff. I’m glad it’s working!

Good job….happy flying!

Great Job!

Still have a Slick on the right side? Does this mag use a ‘shower of sparks’ for replacing the impulse coupler?

I once knew a guy who used a rag for that and then forgot to remove the rag and busted his accessory case.

Hi Tom. Yes, still have a Slick mag on the right side. No shower of sparks. The P-Mag is a pretty smart cookie and able to detect when starting. In that mode, it delays a spark until 4 degrees after TDC. The starts since installation have been very quick and easy so this appears to work quite well.

Thanks

I may have something to put two on someday.

Fantastic!! 🙂 Two of them reportedly maximizes the efficiency of the advanced timing. It’s just money. 🙂

JUst had Barrett put 2 on the engine they are building for the Eagle.

I’m sold just on what I’ve heard.

Fantastic Ron!! I don’t think I’ve ever posted it but I installed a second p-mag a while back and I am still a fan!