In my last post, I showed some photos of the oil cooler mounted. Like this…

I now had to get air from the high pressure side of the plenum (above the engine) into and thru that oil cooler.

Normally, I would create a foam mold and then fiberglass it to make a duct. However; I’ve been doing a lot of 3D printing lately and decided to try that approach.

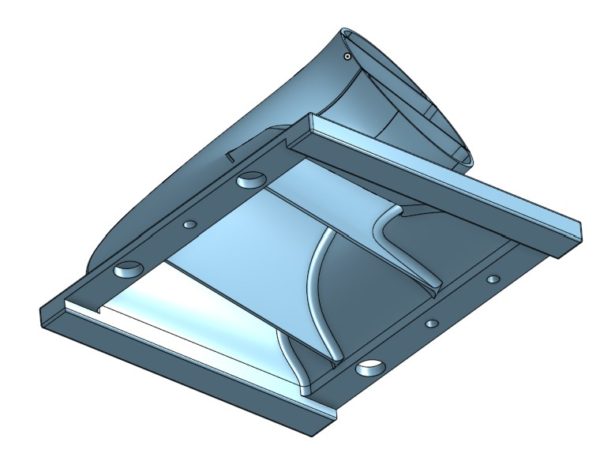

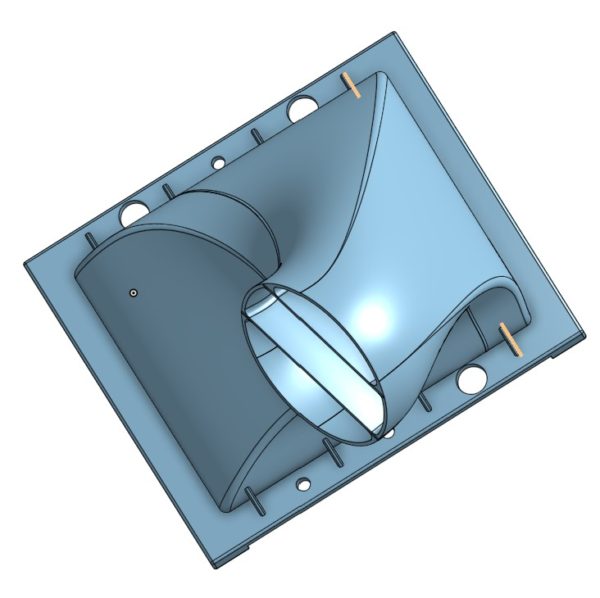

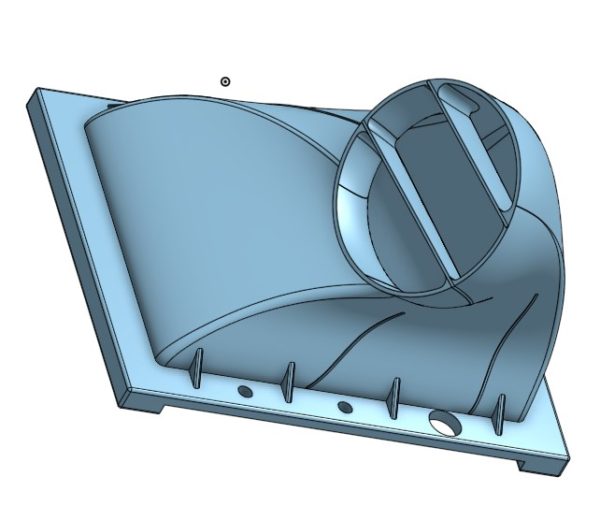

It starts with modeling the duct in 3D drawing software and then printing it to test the fit. Of course, I rarely get it right on the first attempt so it is an iterative process. At this point, I’m printing with PLA filament which doesn’t have great temperature resistance. So, it will probably melt in this application. My plan around that is to get it designed and proven to work and then I’ll print it in a higher temperature, and more expensive, filament.

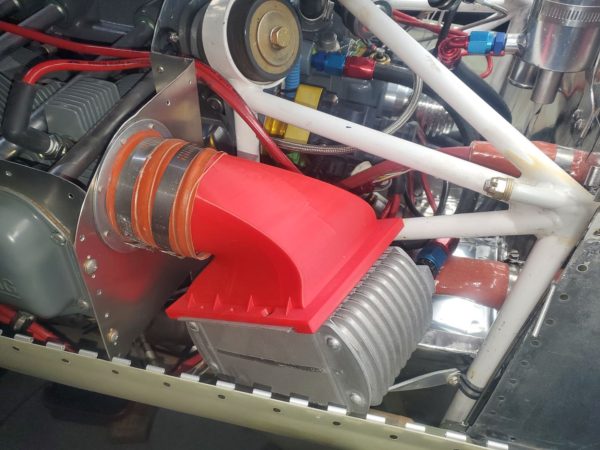

What you see here was version #4. It has three guide vanes on the inside in an attempt to turn the air around that rather extreme curve so that the entire oil cooler is receiving air and cooling the oil.

Here are a few of the test prints and then version #4 in red.

And finally, installed on the airplane.

Your high-tech skills amaze me. Looks good.